Laser projection for woodworking

For decades, laser projectors from SL Laser have been used with great success for woodworking. With the positioning of free forms on CNC machining centers, the first laser projectors from SL Laser defined the market. In the meantime, the application possibilities of the ProDirector 7, the ProCollector L and the positioning lasers have been extended to many other areas of application. Outstanding precision, ease of use and adaptability to a wide variety of spatial conditions are required in woodworking in particular. Be it in the workshop, furniture production or in the woodworking industry.

Advantages for woodworking

Precise laser projection on CNC routers. Expensive templates and time-consuming inspection runs are no longer necessary.

Rejects and damage to tools and suction cups is reduced – thanks to precise positioning on components.

In furniture production time and money is saved by the millimeter-precise positioning of fittings and drill hole markings

By using3D measurements he ProCollector enables precise scanning and projection in staircase construction or fitted kitchens.

Typical areas of application for our lasers in woodworking

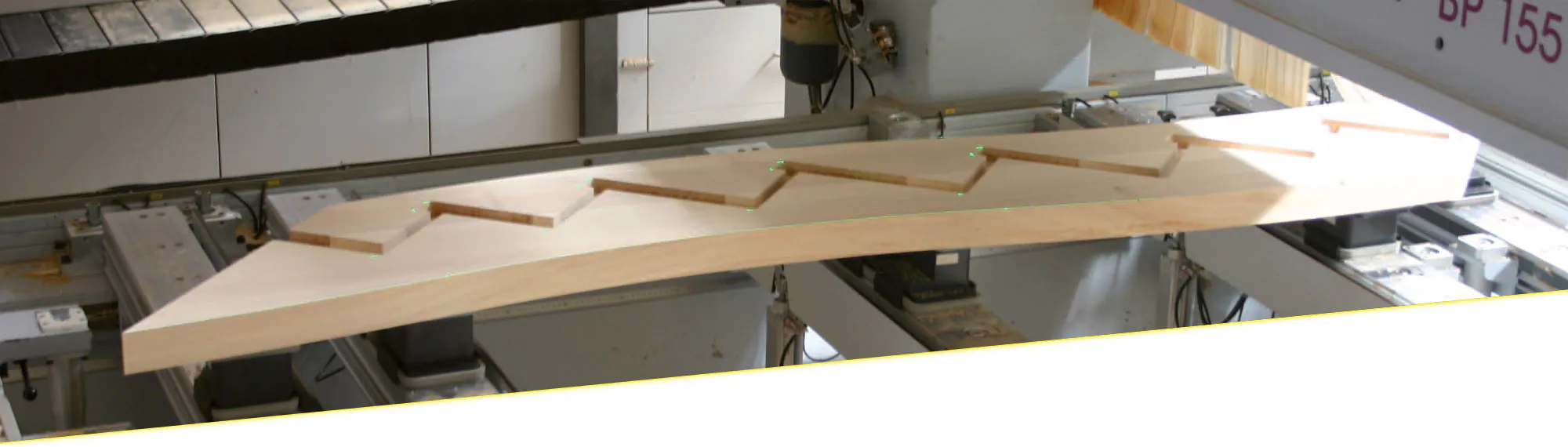

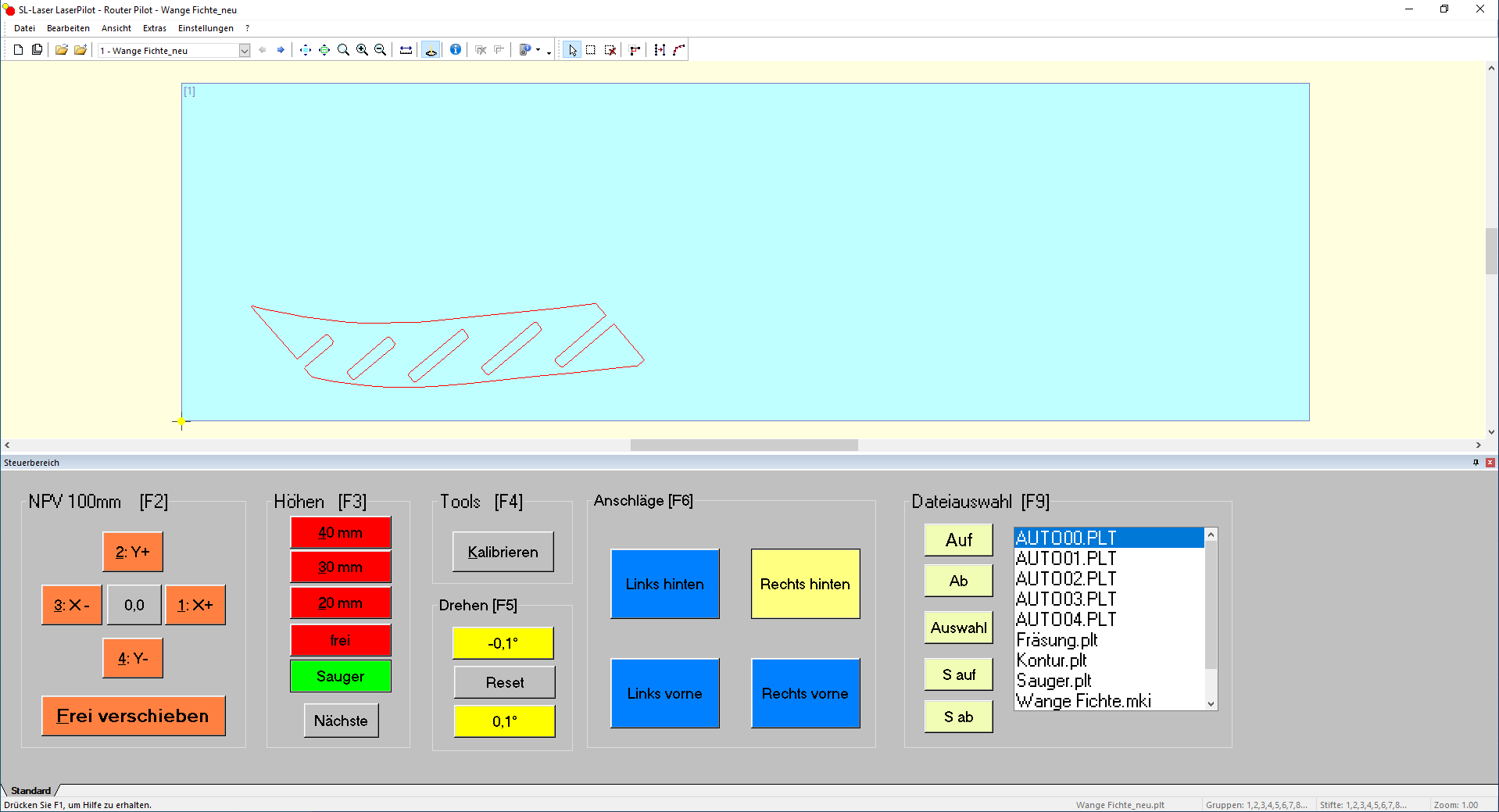

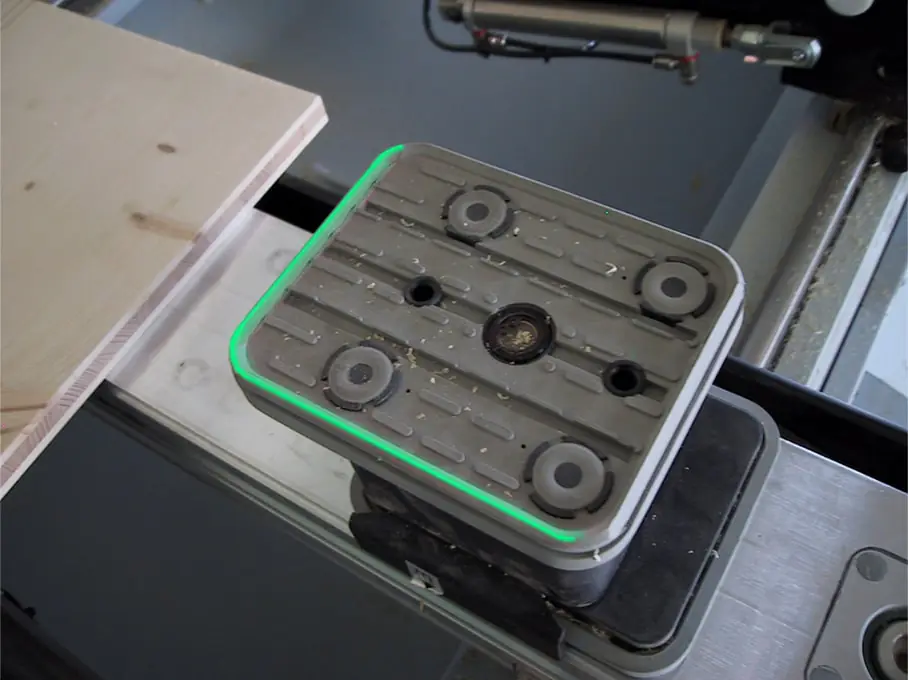

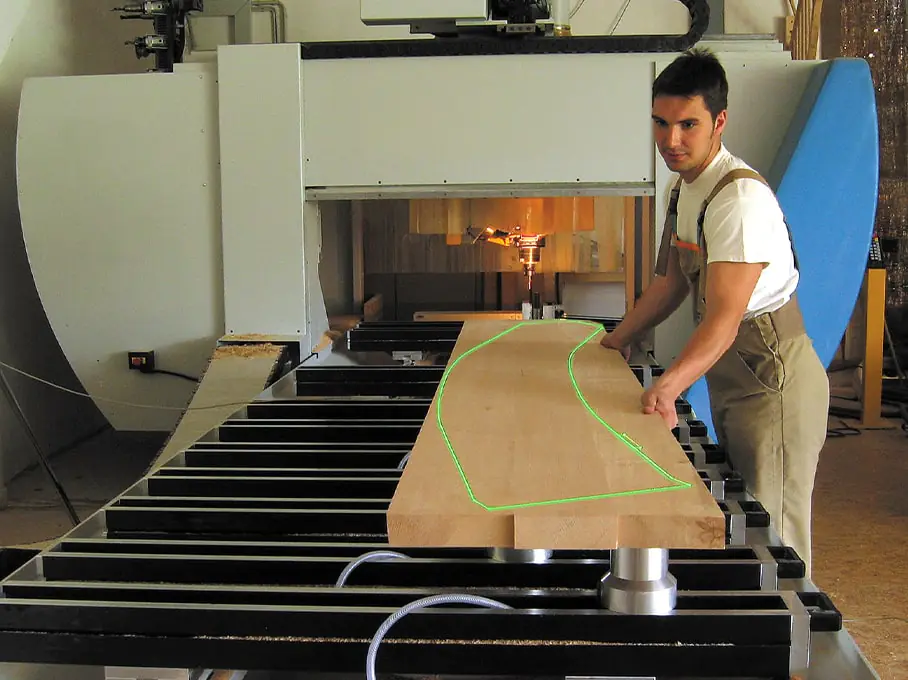

The best-known application for the ProDirector 7 is its use as an effective set-up aid for CNC routers. This primarily involves the precise and fast positioning of suction cups, workpieces and contours for all stages of processing or production. In the woodworking industry, the ProDirector 7 is also used as a multi-projector system to display various processes such as rows of nails and screws in parallel for extremely large components. In carpentry or in the furniture industry, laser projection serves as a precise template for 3D work steps.

Further information on the application in woodworking

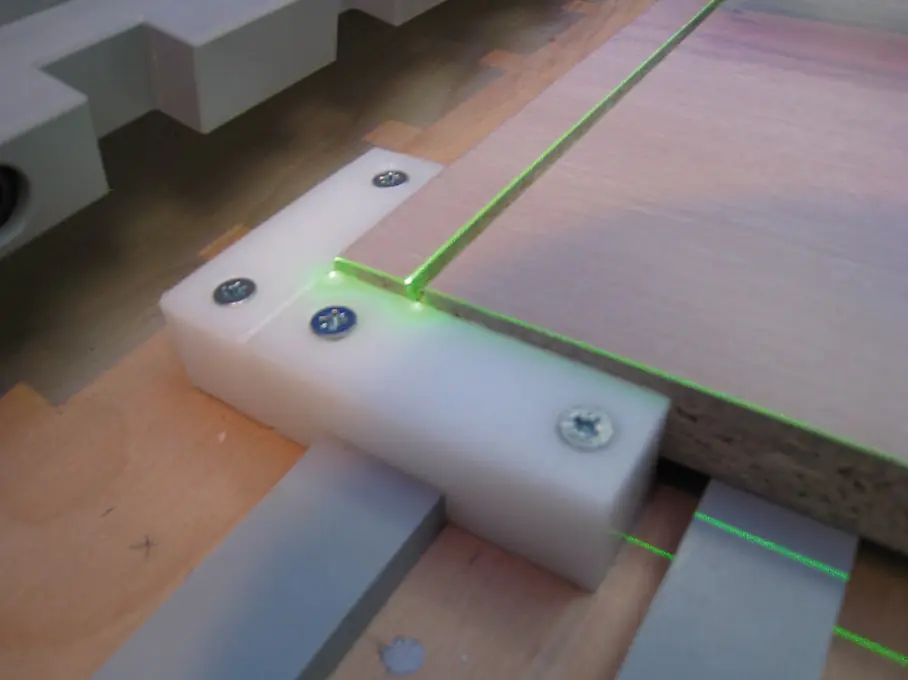

Laser projection in the CNC machining centers

The drawings with positions, outlines and guide lines are created by the software or the control console. Then they are sent to the ProDirector 7 via the CNC router control. The laser projector converts this data into laser lines and projects them 1:1 onto the work table or blank. This saves the creation of templates or inspection runs with the tool in place.

The extremely low error margin reduces the proportion of rejects. The exact positioning of the tools prevents damage to the suction cups and eliminates the need to realign the workpiece.

Laser projection in the furniture industry

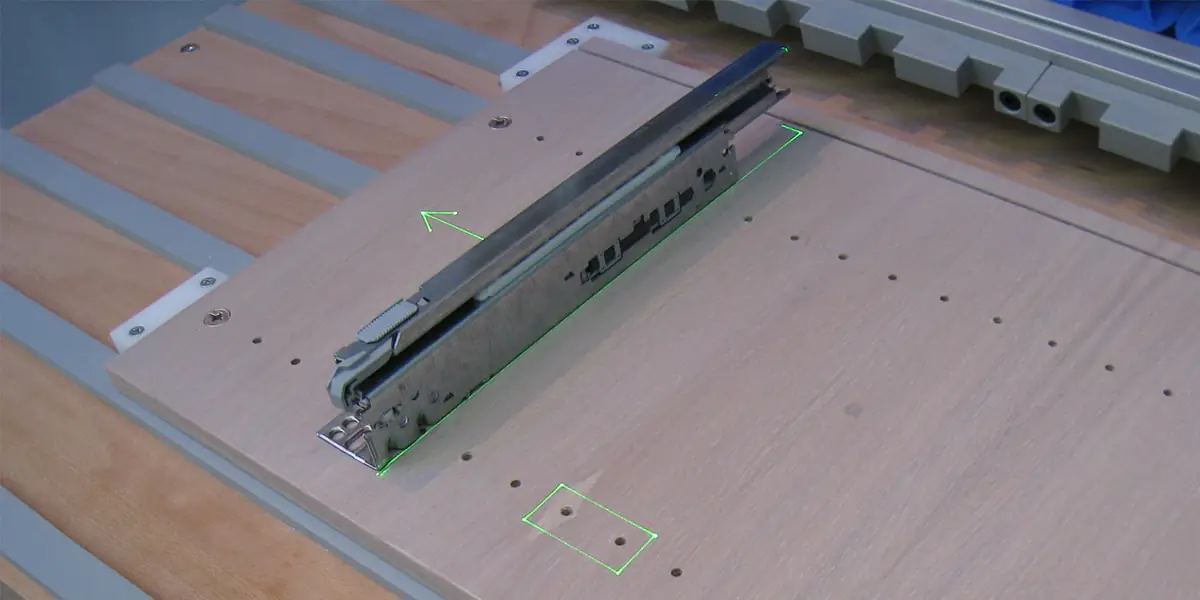

In the furniture industry, everything revolves around fast and precise work on the workpieces. Here, laser projection is used in the production of components, but is also used to position fittings. The laser projectors display the contours of the fittings or strips, which can then be fitted and assembled by colleagues with millimeter precision. They also use the projection of the drill hole markings for this purpose.

The next step is quality control. The laser projector is simply switched on by remote control for the corresponding laser projection of the step sequence.

The ProCollector L for 3D measurement in interior design

This easy-to-use measuring system is used for 3D measurements, e.g. in staircase construction or for fitted kitchens. You select the required measuring points for the drawing using the clearly visible laser point. Using the stored data, the ProCollector L automatically scans horizontal or vertical courses on the wall and on curves.

The progress is displayed on the graphical user interface. The finished drawing is transferred to the CAD program as a DXF file. The drawing can be projected onto the components as a guidance system to aid set-up and as a work template.