Projection systems in the concrete and construction industry

The use of projection systems from SL Laser in the construction industry and for precast concrete parts has been established for decades. They depict precise and true-to-scale outlines, patterns and shapes on surfaces all over the world. Using CAD data as a basis, they create virtual, visible templates. ProDirector 7 simplifies and improves processes by visualizing even complex 3D information. But SL Laser offers even more. In the construction industry in particular, the ProCollector L measurement system can be used to effortlessly create an error-free measurement for many production and assembly processes. It then serves as a projection template.

Advantages for the construction industry and precast concrete production

The ProDirector 7 calibrates itself automatically for precise projections on the table, even in a networked system.

The projectors enable parallel work steps and carry out the final inspection / quality assurance at the same time.

The ProCollector L measures and projects CAD drawings for easy calibration – even on curved surfaces.

On request: Customizable software for integration into control consoles and guidance systems for the practice.

Typical areas of application for our laser systems in these sectors

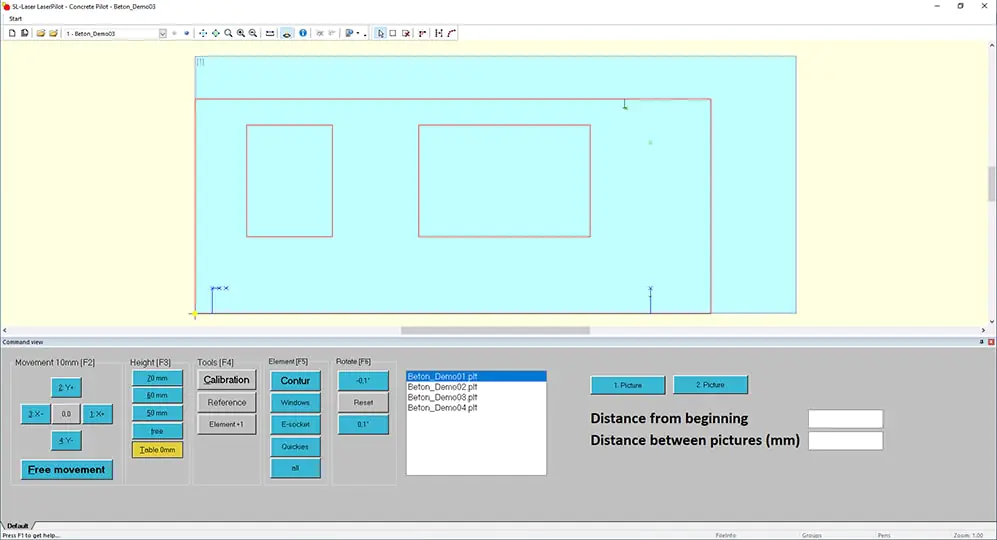

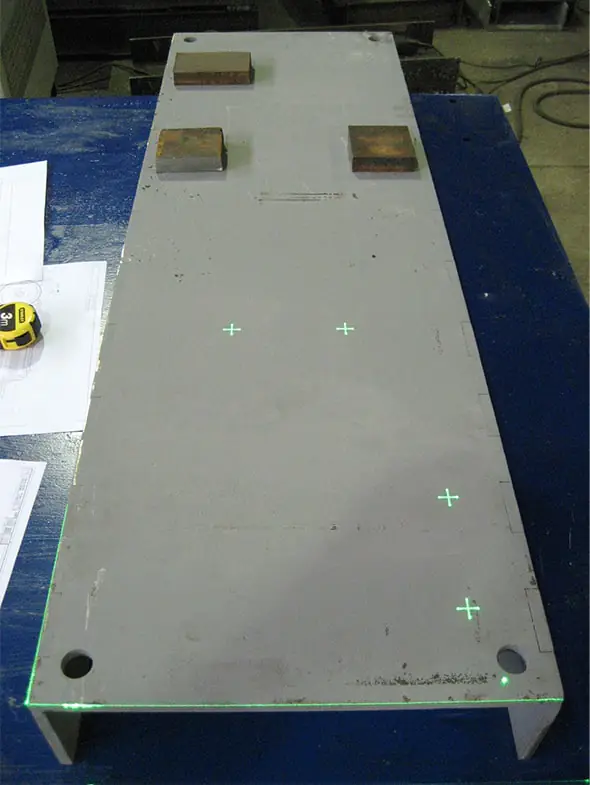

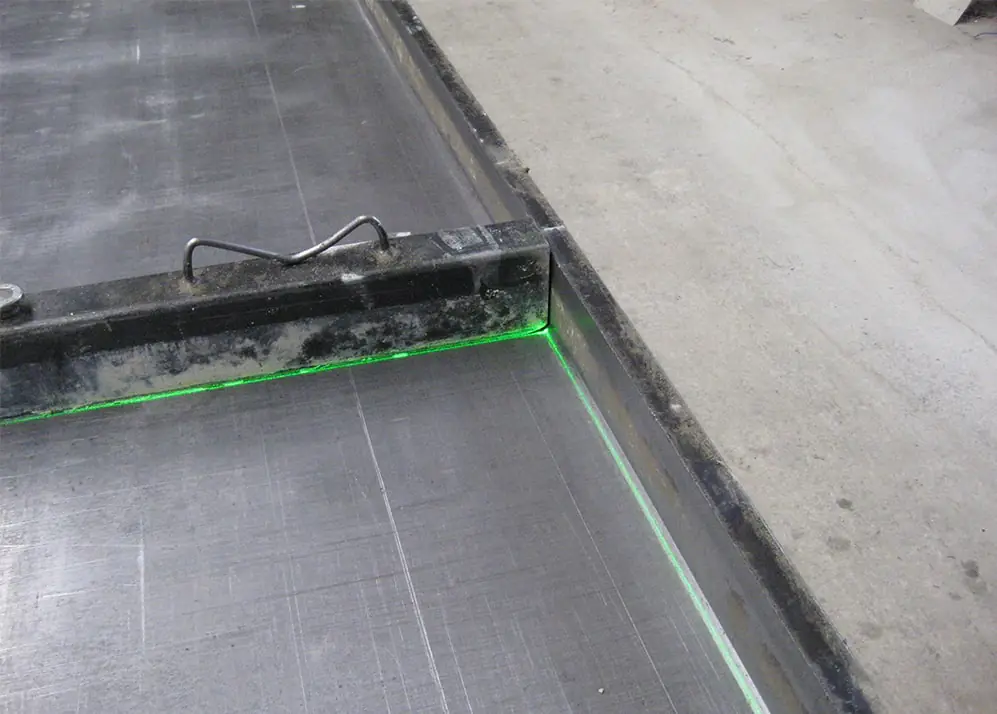

The ProDirector 7 and the ProCollector L are used for various processes in the construction industry and in the production of precast concrete parts. The ProDirector 7 calibrates itself automatically and projects lines and points onto the table at a ratio of 1:1. This enables the positioning of frames, reinforcements and formwork. If you use long table applications, a coordinated network system of several projectors works with exact calculation of height and angles. The ProCollector L collects data with just two measuring points per vertical surface and transfers it to the DXF format for CAD programs.

Further information on use in the concrete and construction industries

The ProDirector 7 in the concrete industry

With a trolley on rails, the ProDirector 7 automatically calibrates itself to the respective positions. It projects all the necessary markings for the section being processed. The data required for this comes from the CAD system. They are selected by remote control or directly on the touchscreen of the SL Laser industrial PC. The respective tasks and positions of the frames, boxes and formwork are projected precisely.

Our developers are happy to adapt the software to specific requirements. Integration into the control console or the conveyor control system is also possible.

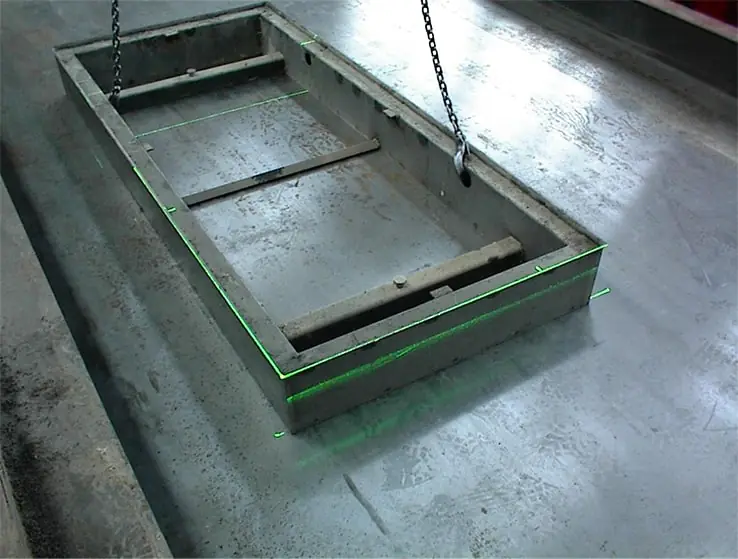

Laser projection for precast concrete parts

When working with pallets, the ProDirector 7 recalibrates itself for each incoming pallet and projects the necessary work steps. In the circulation system, several projectors at the respective stations enable different work steps to be processed simultaneously. This means that frames, formwork, reinforcement and the final inspection are carried out in parallel in one pass.

The final inspection and quality assurance can thus be combined into one work process. The recorded data is stored in the system and can be used in the reporting system.

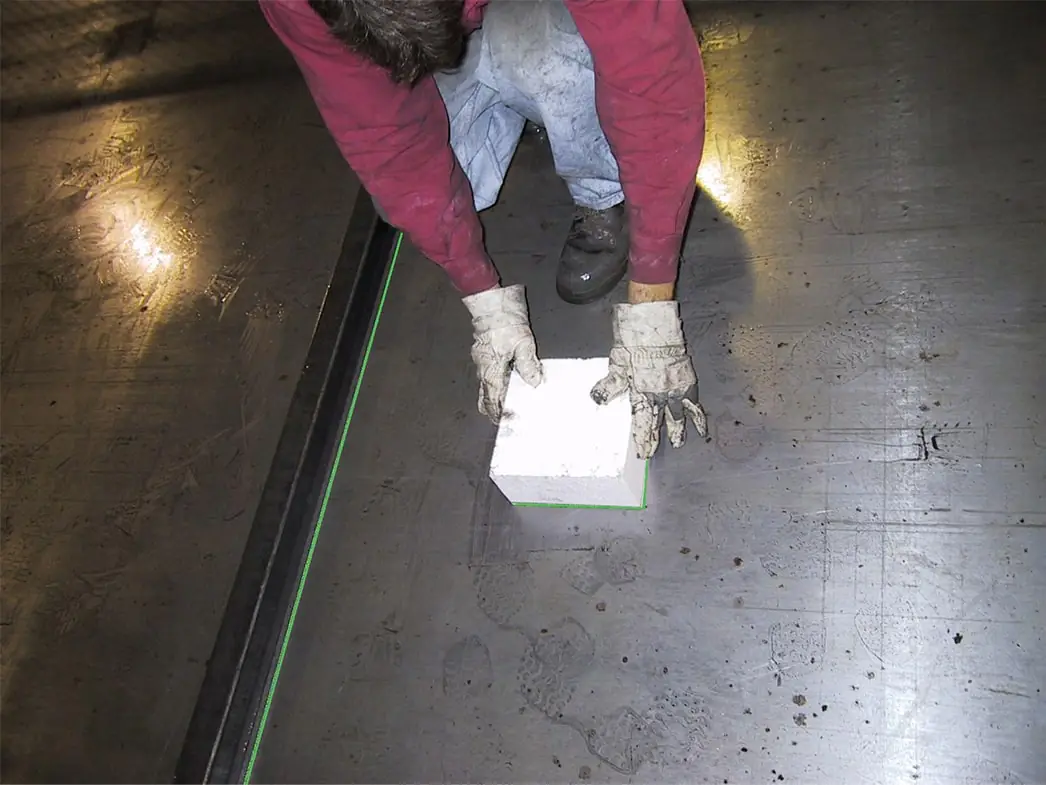

Working with the ProCollector L measuring system

The ProCollector L measuring system measures surfaces, stairs and curved surfaces. The simple procedure eliminates the typical recording and transmission errors when targeting corners and edges. It projects a CAD drawing that it has calculated or is already available onto the workpiece or component in question. It then maps the floor plan.

The exact calibration can then be carried out on the surface to be machined. This makes the work considerably easier. Once the data has been processed further, it can be transferred to production without any loss of time.