Laser projection for prefabricated wood parts

The entire range of SL laser products is used worldwide in the manufacture and processing of prefabricated wooden parts. Measurement systems for measuring staircases in interior construction, for example, are just as much in demand as positioning lasers for aligning workpieces. However, the ProDirector 7 with its variants for medium and large distances takes the lion’s share. Depending on the size of the workshop and components, the laser projector is either permanently mounted under the ceiling or runs on a rail system. Several projectors can be installed as a parallel network system. The ProDirector 7 projects all the required specifications under software control, minimizing the error rate and waste.

Advantages for the wood industry

The interaction between ProCollector and the CAD system speeds up the design of built-in parts, for example.

In production, ProDirector 7 optimizes work processes and results with precise specifications for machines and workers

In glulam production, the laser projection shows positions for press brackets and molded parts: increased efficiency.

The ProDirector reduces set-up times by up to 70% and optimizes repetitive tasks with programmed sequences.

Typical areas of application for ProCollector and ProDirector 7 when working on prefabricated wood parts

ProCollector can already provide valuable services as a measurement system when planning the construction of prefabricated timber parts. The data collected is transferred to the CAD system for subsequent projection and converted. The exact cutting of the wood is prepared with the projection of the frames and outlines for fine adjustment. When using CNC routers, saws and planing machines, ProDirector 7 provides all the important markings, including the positions for suction cups and tools. The quality control and final inspection for the finished parts is considerably shortened and simplified with the laser projector.

Further information on the application in the field of prefabricated wood parts

Laser projection in wooden frame construction

The SL LaserPilot software works together with the CAD system and supplies all the necessary drawings to the ProDirector. The projected laser lines provide millimeter-precise templates for rows of nails and screws, show distances or recesses. In the composite system on long tables, the work for timber studs, built-in parts and cut-outs can be carried out in parallel.

Changes and new drawings are imported as required, or the images are mirrored, repositioned and projected at different heights. The 1:1 factor of the projection provides the necessary security for precise work.

Laser projection for glulam beams

The position of the press frames and the shape and alignment of the molded parts are projected simultaneously for glulam beams in the composite system. The projector is used in groups or movable. The projector moves to defined positions and projects the relevant section of the drawing on a scale of 1:1.

If the finished glued laminated wood is to be processed further in the CNC system, its contour is mapped and moved by software so that it fits exactly to the new position. Once the data has been transmitted to the machine control system, work can continue with minimal delay.

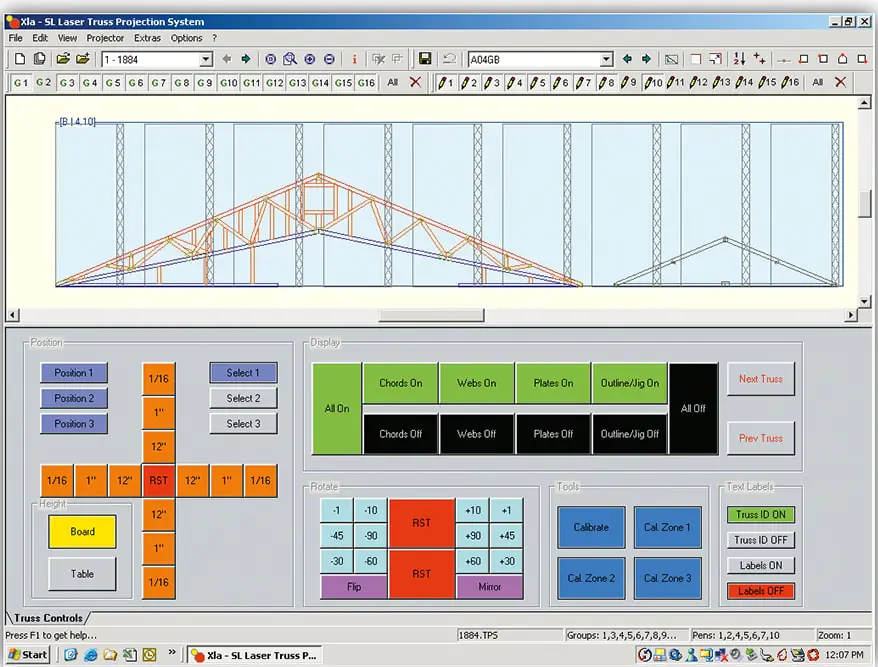

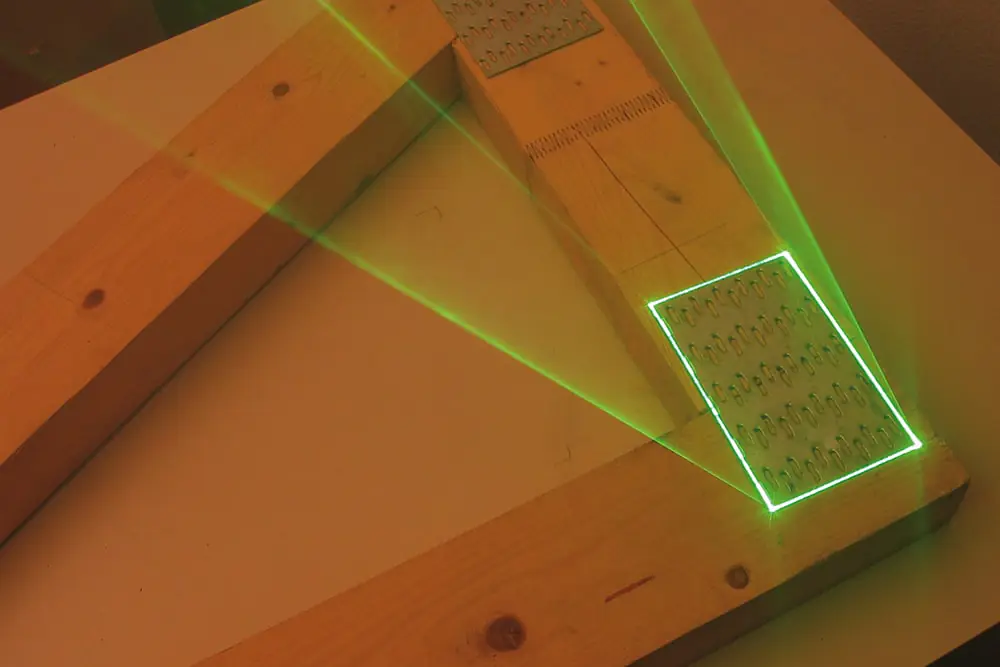

Laser projection for nail binders

The projection of the respective work phase also optimizes the assembly of a roof truss, for example. Each different set-up status is passed on to the ProDirector in seconds by the LaserPilot program without templates, which displays all positions and outlines. The complete contour of the nail truss, the position of the nail plates and stops are displayed.

This saves up to 70% of the set-up time. There is also a significant enhancement to the software. Frequently repeated tasks can be programmed without much effort, allowing them to be called up immediately during work.