SL Laser – 3D laser projection in craft and industry

- Brief introduction to laser projection in production and assembly

- Higher precision – greater satisfaction

- The 3D laser projection in industry and trade

SL Laser has been on the market since the early days of laser projection as a setup aid and virtual template in production and assembly. With literally thousands of systems installed, our laser projectors facilitate and optimize work in many companies around the world.

System specifications

for the ProDirector 7 laser projector

Position Accuracy

± 0.014“ (0.35mm) at a distance of 15‘ over 17‘ x 17‘ (4.5m x 4.5m) area (equals to a 60° projection)

Field of View

Horizontal: max. 80°, Vertical: max. 70°

Laser

Green: 520-525 nm, FC-lasermodule

Laser Class 5 mW

International: Class 2M per IEC/EN 60825-1:2015-07, CE certification

USA: Class IIIa per 21CFR 1040 (CDRH)

Power Requirement

80-240 VAC 50/60 Hz

Dimensions

Length: 355 mm/18.90 “, Width: 120 mm/6.69 “, Height: 190 mm/11.42 “, Weight: 5,8 kg

Brief introduction to 3D laser projection

in production and assembly

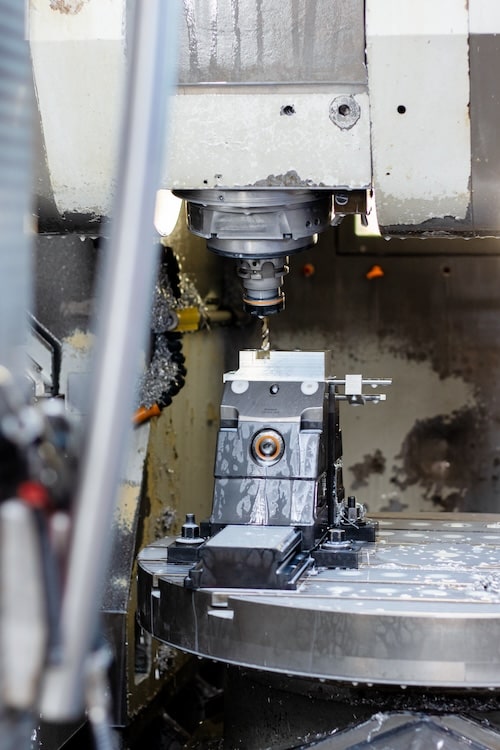

The projection of edges, drill holes or outlines by laser projectors is already the daily routine in many industrial and craft enterprises. Instead of time-consuming preparation of expensive templates, the ProDirector 6 projects all necessary templates onto the workpiece or even the work table. At the touch of a button, the device switches to the next work step or layer. So the work can continue quickly, precisely and safely. Reductions in working time of 25% or more are the norm.

However, added to this is the unparalleled precision of the systems. This precision not only improves the quality of the products but also reduces the margin of error in the company. Measuring and transferring plans to workpieces is as time-consuming as error-prone – and can be eliminated. To top it off, many quality management tasks can be accomplished just as easily. The colleague simply has the projection repeated step by step and checks the work done.

Hardware

performance description

- Precision high-speed scanner with push-pull output stages

- Electronics in modern SMD technology.

- Integrated embedded PC with 800 MHz, 4 GB memory

- Optimized receiver sensor for reflected radiation

- Data input RS232, RS485

- Control lamps for mains voltage and information signal

- Mains filter in the power supply

- Switch-mode power supply with an input voltage of 100-240 VAC

- Industrial aluminium housing to IP54 with optimized surface for heat dissipation

- Ambient temperature 5-45 degrees, power consumption approx. 70 VA

- CE conformity marking, manual

Do you have questions?

Get in touch – we’re here for you. Our customer service team is happy to provide personal advice and individual support.

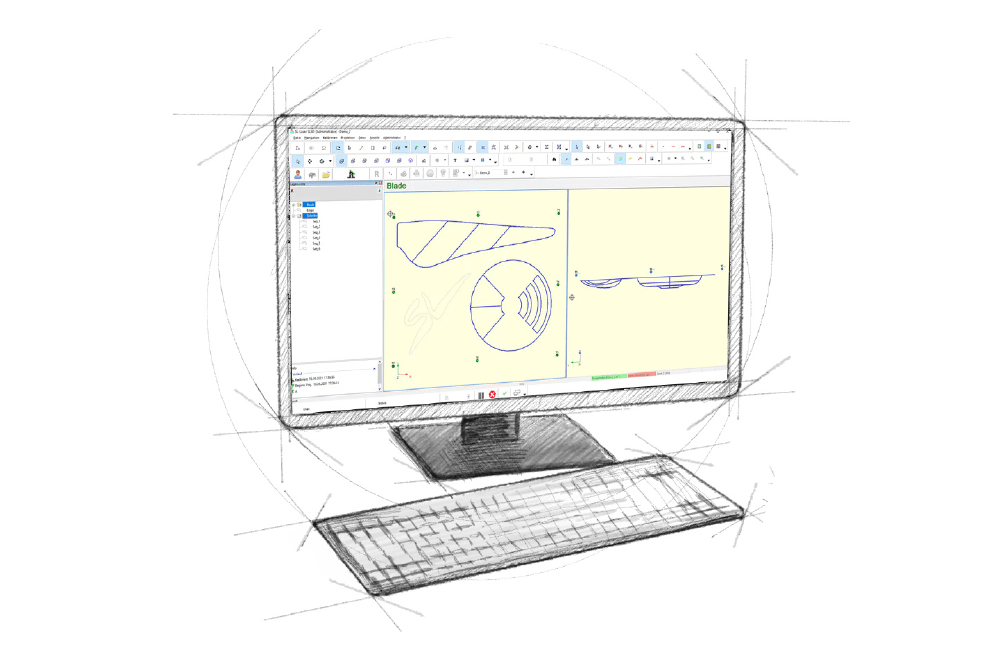

Software-controlled projection

of laser beams

In most cases, the necessary data for the laser projector is simply converted by software from the CAD program. Then it is transferred directly to the projector. The virtually projected templates from the laser projector are as accurate as they are safe for the eyes. The prerequisite for this is the precise calibration of the work surface and the appropriate placement of the projector. With reference points to be controlled, even a movable work table can be quickly calibrated. After that, the workpiece can also be positioned perfectly and automatically.

For very large systems or in aircraft construction, a network of laser projectors is also often used, all of which are connected together. Together with our partners, our laser projectors can also be integrated into a direct installation with the control elements of the systems on request. Doing so the machine and projector can be operated from one and the same console. At SL Laser we have developed special software for different industries, products and applications, which is prepared for most applications. This concerns both the conversion of CAD data and the creation and use of libraries for recurring tasks or components.

The 3D laser projection

in industry or handicraft

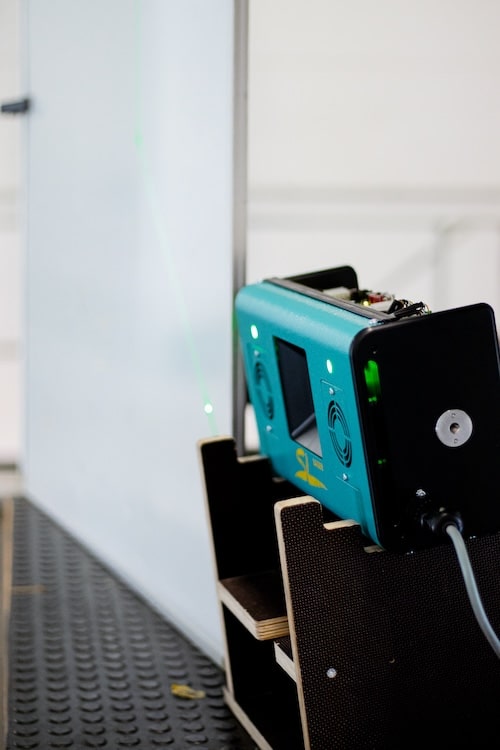

Work motivation increases considerably with a plotter of this kind at work. The eternal uncertainty factor of sufficient precision at work is easily eliminated. At ± 0.35 millimeters, even the assembly of cockpits in helicopters achieves satisfactory precision when several dozen switches and buttons are to be precisely installed and mounted. Depending on the conditions at the workplace, the projection can be done with green or red laser beams.

In addition to the possibility of using the laser projector in a network, many companies also use a system that can move the laser projector under the ceiling like on a track. In this case, the different positions are already stored in the system so that the next work step at the other end of the assembly line can be carried out without any transition. The projection fits perfectly!

The next level using a laser projector is the work with 3D-Cad. Especially for complex components and prototypes, 3D-CAD data is used to depict a coherent three-dimensional overall impression. On the other hand it shows the involved layers in their interaction. The 3D-CAD data can also be used as a basis for working with laser projectors.

Such tasks are often found in the production of carbon fiber components, but also in other industries. Here, several projectors are often used, which simultaneously project the elevation in the different planes as a multi-form.

For this purpose SL Laser developed a special software e.g. for 3D composite applications. SL3D allows trouble-free working with the 3D data as well as several projectors. SL3D imports 3D CAD data from all common formats like STEP, IGES, DXF or even XML. The conversion of the 3D data allows a graphical 3D view in the projection. The image contents are displayed in up to four windows at the same time to match the projection. In addition to the graphical images and projections, PDF or Jpg files can be displayed, describing the respective work process.

As each layer is processed, the correct projector is automatically selected. In aircraft construction, conventional 2D projection often proves to be insufficient. Especially for the multitude of handles and holders, the exact position in relation to the environment is crucial. The use of robots is out of the question due to space constraints as well as the fact that series production is rarely possible. The usual measurement errors cause large expenses, which are avoided with 3D laser projection.

3D laser projection plays an important role in quality assurance. The sampling of complex components is considerably simplified and accelerated with the help of laser projection. This is especially true for rivet, screw or nail positions on curved and offset surfaces or in layered construction. Individual elements are highlighted and brought into focus step by step for follow-up inspection. This saves considerable time by eliminating the need to identify and re-measure the various positions.

Installation and training

for 3D projection

Certainly, this next level of 3D projection in assembly and production requires much more knowledge and skill in setting up, adjusting and actually operating the applications. However, SL Laser has its own training program available, which has been optimized over the years by working directly with customers. Training can be conducted either on-site or online. Experienced trainers master the subject matter in such a way that the training contents are adapted to the respective challenges of the customer. The learning of superfluous theory or content far removed from reference is avoided and rather the application to the actual task is trained.

SL Laser has always concentrated on the unconditional fit into the existing workflows and processes in the development of the laser projectors. The same path is followed in developing the user software and all the training courses for the customer. This philosophy allowed us to succeed in initiating worldwide sales of our products since the 1990s. Plus we are proud that we’ve always been able to record a high level of customer satisfaction.

Feel free to contact us at any time. We will gladly answer all your questions without obligation!