Laser projection systems in the stone industry

The stone industry has a particularly wide range of applications for SL Laser’s projection systems. In this highly competitive industry, optimized precision and increased production efficiency are welcome. The reduction in time-consuming set-up times is a significant benefit. The application runs from the first measurement to the cutting and processing of the orders – from the same panel. The specially developed programs for our products enable 3D measurements, accept CAD data, convert it and specify all work steps in series or in parallel.

Advantages for the stone industry

Clear advantages: CNC centers achieve shorter set-up times and faster throughputs with reduced scrap.

During nesting, different jobs are cut quickly from the same panel, templates are replaced by projection.

The calculation simplifies the positioning and processing of heavy panels without physical displacement.

The LaserPilot software enables parallel work steps and is compatible with most CAD programs.

Suitable products for the stone industry

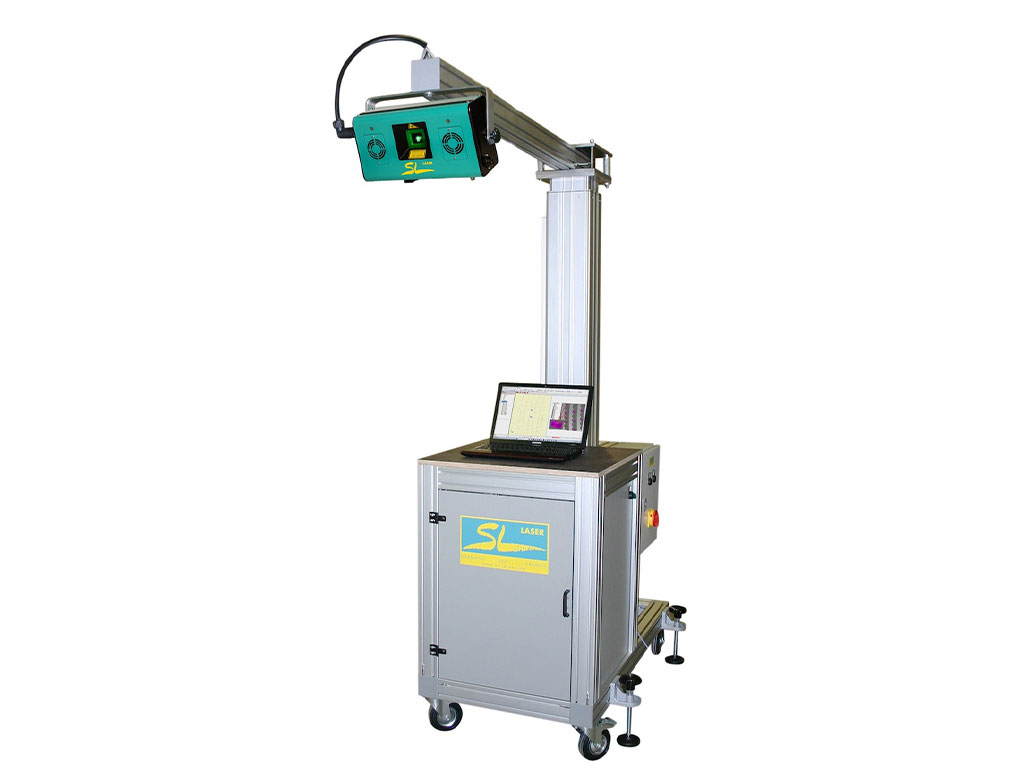

Laser light projector ProDirector 7

The ProDirector 7 projects under the ceiling, the next work steps or entire construction plans from the 2D CAD or 3D CAD system onto the workpieces. Can be used for distances from the laser to the application of up to 6 m.

Typical areas of application for our lasers in stone processing

Laser projection saves costs and increases quality. This applies to work in CNC machining centers, when measuring stairs or walls and even when laying stone inlays. No company wants to miss out on these benefits once it has tested SL Laser products. In the CNC machining center, the throughputs are significantly faster with drastically reduced waste. You save working time and material when cutting and processing stone slabs without displacement. The ProCollector L is also used in mobile applications, e.g. for measuring and projecting data in wall or stair construction.

Further information on applications in the stone industry

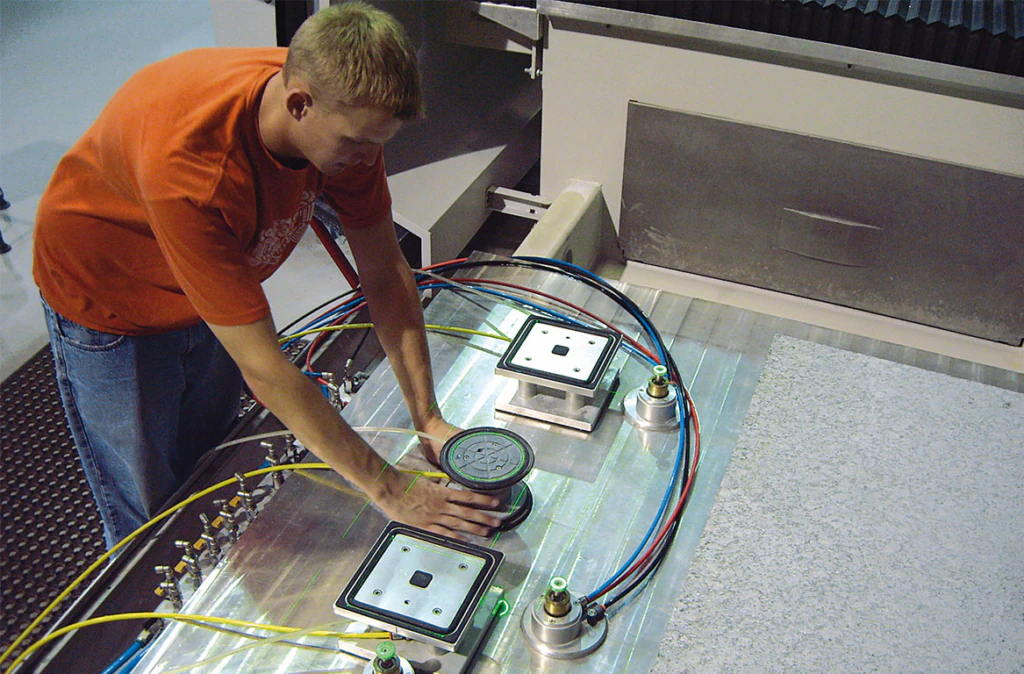

Laser projection drastically reduces the set-up time. The ProDirector 7 works either directly integrated into the control console of the CNC router or it converts its data from the CAD program. The precise positioning of workpieces and suction cups eliminates the time-consuming inspection runs with the tool in place. Expensive damage to suction cups is impossible.

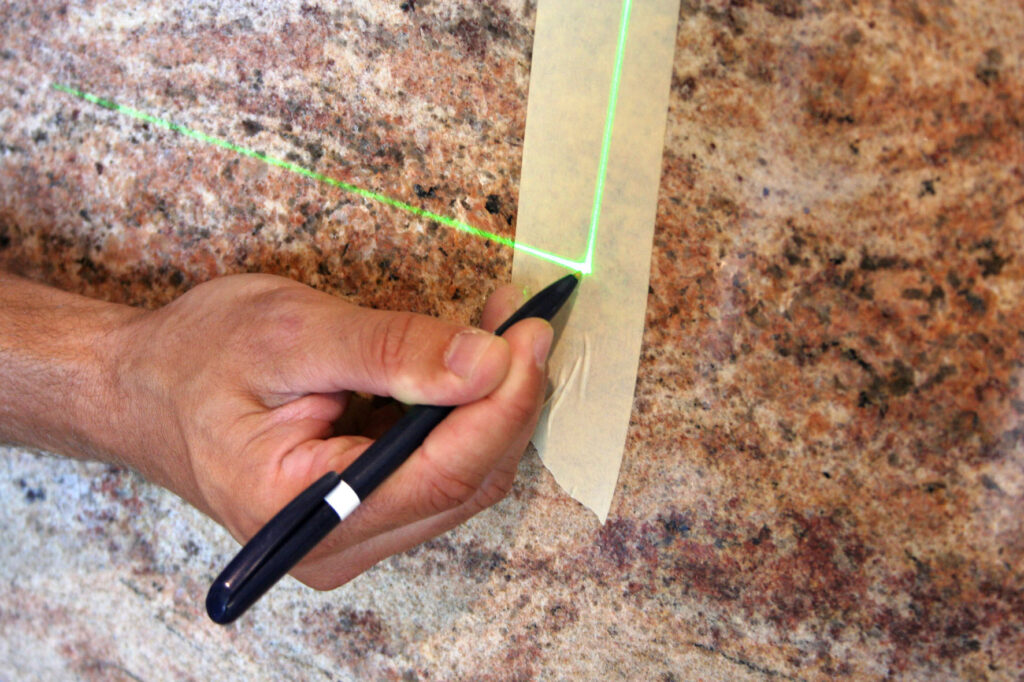

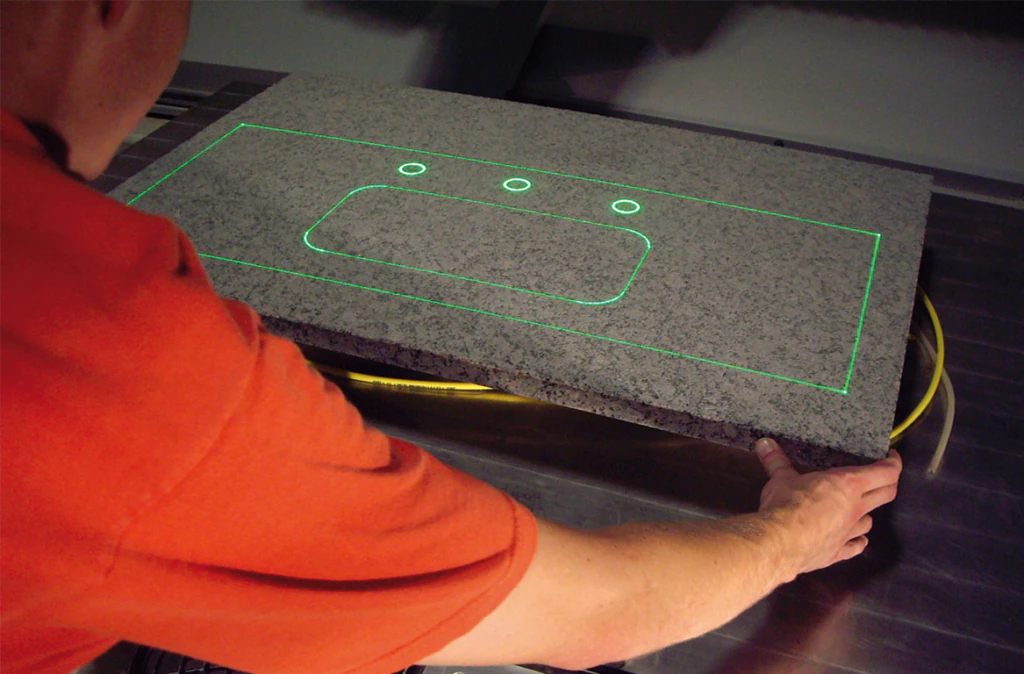

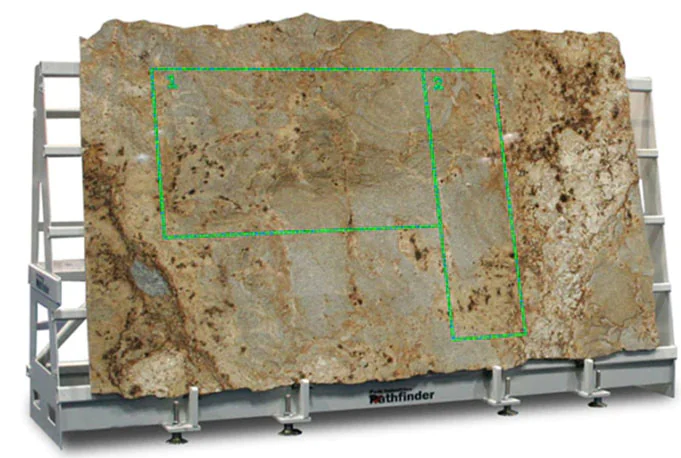

The ProDirector 7 projects the drawing with all positions and contours onto the surface at a scale of 1:1. The green laser beam is clearly visible on the blank or table and makes work easier.

Complete different jobs from the same panel in no time at all. The projection of laser beams replaces costly templates. The projector projects the contour from the first CAD drawing onto the panel. Now another drawing with the corresponding contour is added. Use the mouse to rotate and move these two or more contours in relation to each other on the screen to create the ideal layout.

The ProDirector projects the results onto the sheet. You achieve your work goal with the least amount of work and time, without the use of materials or tools.

Take advantage of the flexibility of the ProDirector 7 with regard to position changes. The contours of the drawings are simply converted for the various work steps so that the heavy granite slabs no longer need to be moved. The displacement is only required on the drawing. It is recorded, converted and the change is transferred directly to the control system together with the correspondingly adapted data.

The LaserPilot software supports you in this process as well as in many other tasks. Specially developed for such work steps, this software is compatible with most CAD programs.