Projection lasers and measuring systems for the textile industry

Laser applications such as SL Laser’s laser projectors and measuring systems are increasingly revolutionizing the textile industry. This advanced technology offers precise and efficient solutions for a variety of processes, from material utilization to accurate pattern creation. The use of laser projectors and positioning lasers ensures a significant increase in product quality and efficiency in production. This applies in particular to the minimization of the error margin with correspondingly lower wear. Employees appreciate the quick training, easy operation and rapid processing of orders.

Advantages for the textile industry

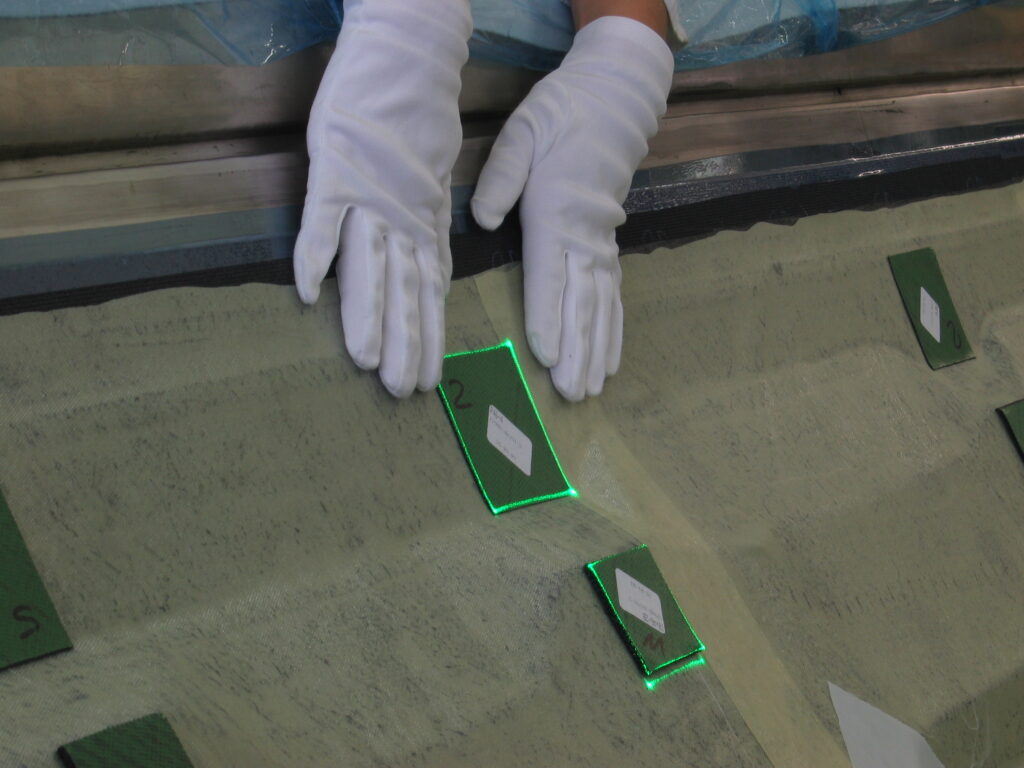

The laser beams act as templates, enabling precise positioning of materials without errors.

The elimination of physical templates for cutting processes significantly saves material and time.

Specially developed software transfers the patterns from the CAD program to the projection processes.

The projection specifications can be saved, edited and modified for future changes or training sessions.

Suitable products for the textile industry

Laser light projector ProDirector 7

The ProDirector 7 projects under the ceiling, the next work steps or entire construction plans from the 2D CAD or 3D CAD system onto the workpieces. Can be used for distances from the laser to the application of up to 6 m.

Typical areas of application for our lasers in the textile industry

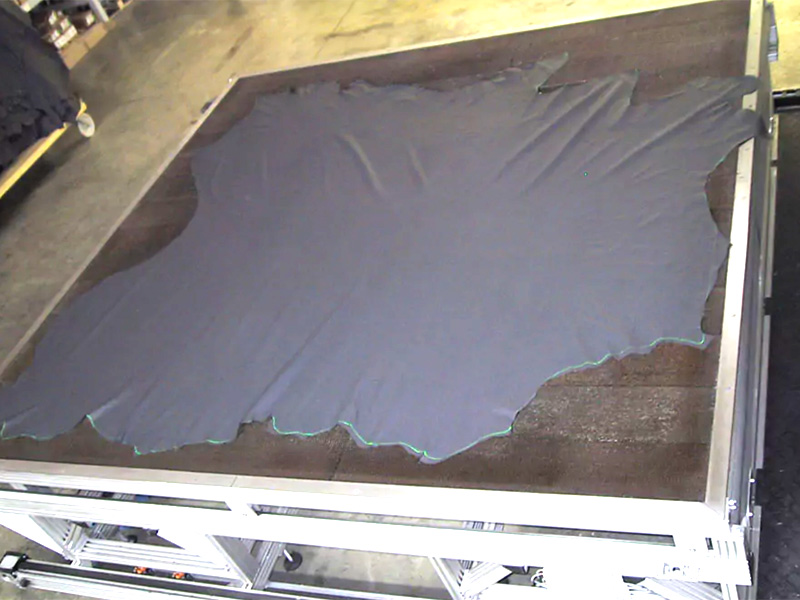

Laser projection demonstrates its particular efficiency when processing canvas, awnings or balloon covers. The ProDirector 7 is ideal for optimizing material cutting and for projecting complex patterns. The CAD programs or OEM software are connected via special interfaces. The customized SL Laser software projects the designs onto the material at an exact 1:1 scale. Training employees in this technology is straightforward and they can quickly take over control of the devices.

Further information on the application in the textile and composite area

Precision is crucial in the production of pool and solar system covers. The ProDirector 7 makes it easier to create exact cuts according to specifications. The ProCollector L mobile measuring system simplifies the manual recording of the necessary dimensions, which is otherwise a complex and error-prone process. This device makes it possible to record measurement data easily and accurately and transfer it directly to a CAD program.

The ProDirector 7 is controlled via the interface and displays precise cutting patterns. Operating the ProCollector L also quickly becomes routine, so that both systems work in synergy to revolutionize production processes.

The ProDirector 7 is ideal for cutting materials for the production of car seats or sofa sets. Many other special applications go far beyond projecting templates for cutting materials. The projection of complex patterns for several layers has also proven itself in the carbon sector. An important area of application is the precise alignment and positioning of components in the manufacture of multi-layer textile products. Expert Systemtechnik GmbH uses our projectors for its 2D cutting solutions for flexible materials.

As an extension to 2D projection, the ProDirector 7 with the corresponding software is also set up for three-dimensional projection. This makes it easier to display multiple layers.

In the fashion industry, laser projectors enable patterns and designs to be precisely adapted to complex fabric cuts, helping designers to realize their visions. This means that test arrangements can be tested without the need for physical intervention. In the upholstery and furniture industry, the laser projectors make it easier to precisely cut and adapt fabrics to different shapes and sizes.

In training, employees can carry out test cuts without the need for fabric. Processes can be saved and repeated as required.