Positioning lasers & projection lasers for composite applications

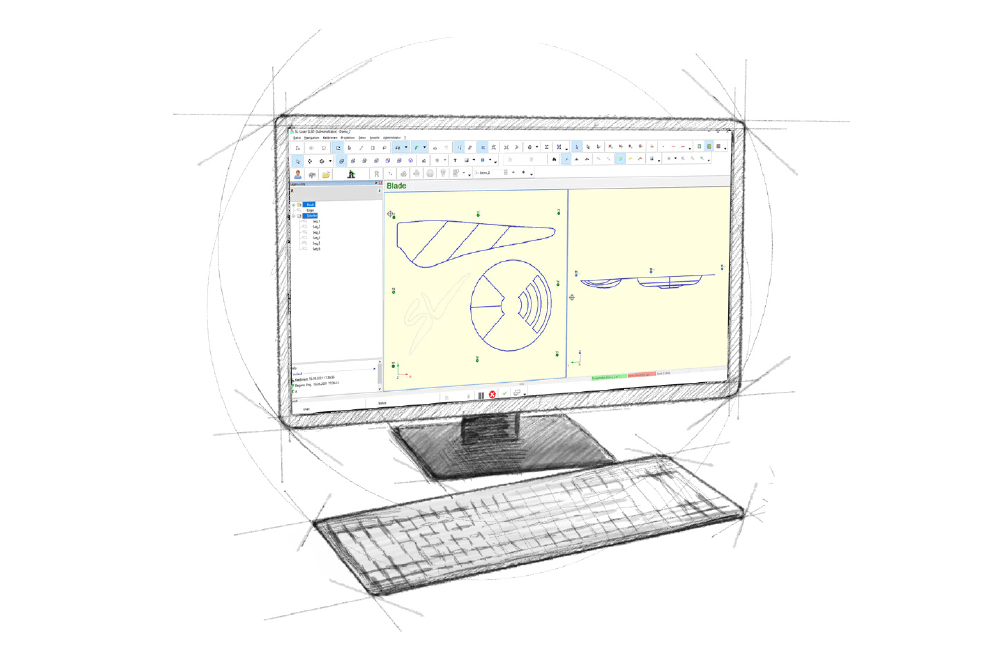

The geometry and dimensions of the layers play an important role in the processing of composite materials. The different properties must be precisely coordinated during the manufacturing process. The exact projection of the contours with the ProDirector 7 laser projector makes the work much easier and speeds up the entire process. The special SL3D software for composite applications provides indispensable services. Software-controlled projection in the production of fiber composite components, e.g. with carbon, minimizes typical errors. The entire process sequence ensures a profitable advantage.

Advantages for the composites industry

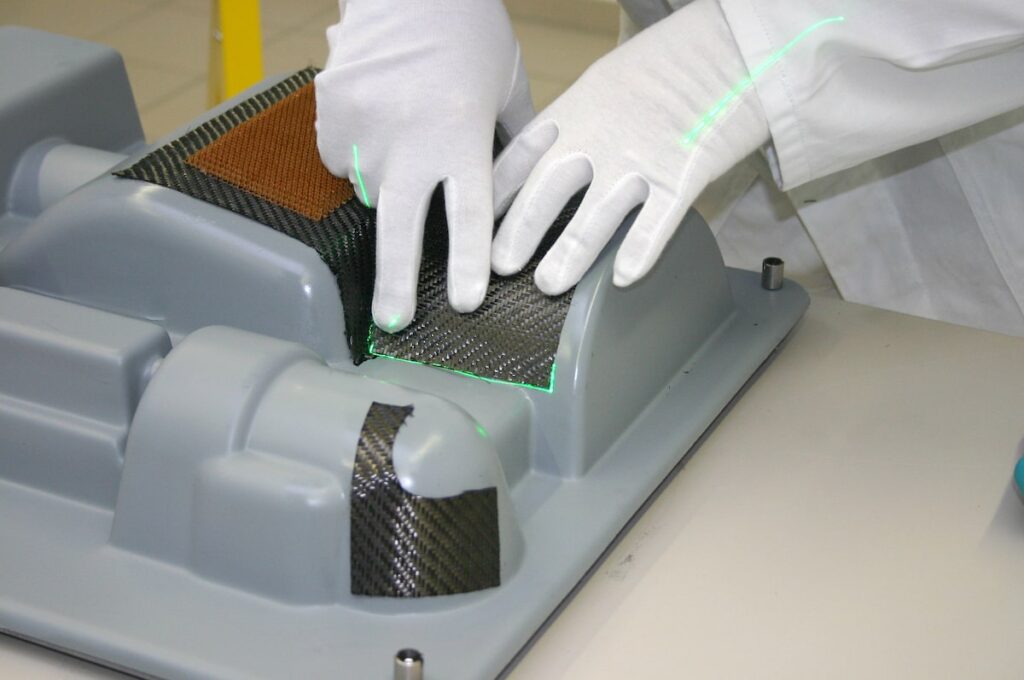

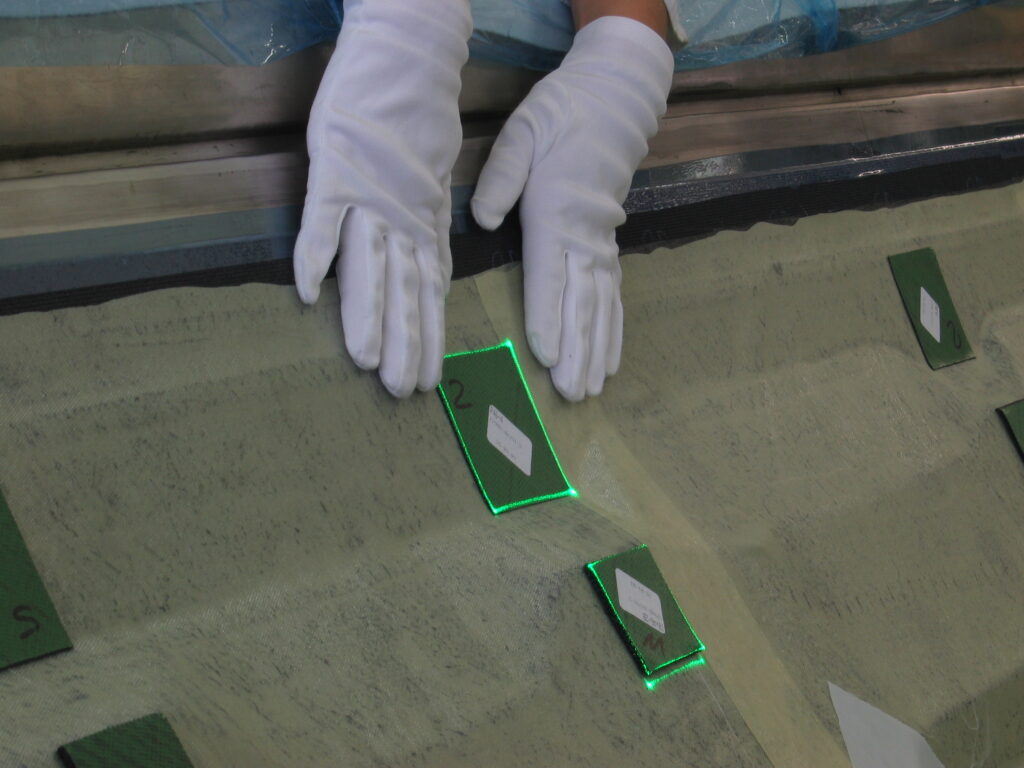

The required layer positioning sequence is stored in the software and perfectly mapped in the process.

Prepregs can be laid without errors as the laser beam template indicates and specifies the exact positions.

The time-consuming and tedious production of templates is not necessary. This saves a considerable amount of material and time.

Protocols of the processes are stored electronically. This allows the projection to be supplemented with additional information.

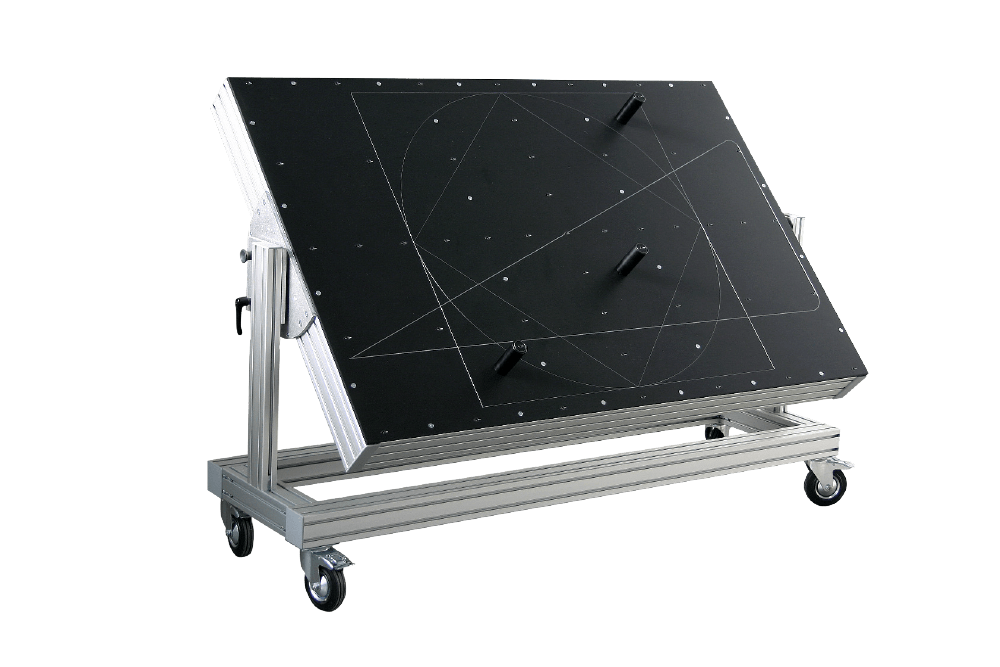

Suitable products for the composite industry

Laser light projector ProDirector 7

The ProDirector 7 projects under the ceiling, the next work steps or entire construction plans from the 2D CAD or 3D CAD system onto the workpieces. Can be used for distances from the laser to the application of up to 6 m.

Typical areas of application for our lasers in the composite industry

ProDirector 7 is used for various processes in the composites industry to optimize development, production and assembly. In production preparation, laser beams facilitate the planning and layout of material cuts. Precise markings on composite materials allow exact positioning and alignment. Assembly instructions are projected directly onto the work surface, simplifying work and reducing sources of error.

Contours and dimensions are checked in quality control. For training purposes or design changes, complex assembly or manufacturing processes can be communicated visually without physical modifications.

Further information on the application in the composites industry

The system consisting of ProDirector 7 and SL3D software is specially tailored to the needs of the aerospace industry. In the production of composite materials, for example in the layup process, lasers show the exact position of each layer under software control. This is essential in the production of aircraft fuselages or wing components. This precision is essential for processing the complex geometry of the components.

The engineers appreciate the integration of multi-projector systems with multitooling, the user-friendly operation and the complete process documentation required for the prescribed quality control.

The ProDirector 7 is used in the production of rotor blades for wind turbines. The precise projection, even from a great height, facilitates the joining of carbon fiber mats. The projection makes it possible to attach brackets, drill holes and markings. The parts can be precisely aligned when assembling the rotor blades. The ProDirector is indispensable in quality assurance and when measuring and assembling other subsystems.

During repairs, laser projectors mark the damaged areas and enable more efficient repair processes. Our software is optimally adapted to the needs of manufacturers.

Composite materials are increasingly being used in automotive engineering and shipbuilding, particularly for the construction of yachts. The laser projectors optimize the joining processes of composite fibre mats, for example by projecting drilling or cutting lines onto the surfaces of complex assemblies or hard-to-reach areas. A visual representation of design changes becomes possible during development. The precise layup of composite materials enables uniform layer thickness and quality for structural integrity. Different work steps are linked and documented simultaneously. The SL3D software can be customized on request.