Laserprojektoren von SL Laser in der Metallindustrie

Bei nahezu allen Arbeitsschritten der Metallverarbeitung unterstützt der ProDirector 7 mit seinen Varianten für mittlere und große Distanzen die Präzision und Effizienz der Produktion. Dabei verteilen sich unsere Kunden über die gesamte Branche. Große Metallbau-Unternehmen setzen ganze Serien der Laserprojektoren einzeln oder im Verbundsystem in nahezu jeder Fertigungsabteilung ein. Viele Werkstätten und Schlossereien präzisieren und beschleunigen ihre Arbeiten entscheidend und sichern sich damit Wettbewerbsvorteile. Gerade im Bereich der Metallverarbeitung spielt die Unterstützung der Projektoren bei der Qualitätssicherung eine wichtige Rolle.

Vorteile für die Metallbranche

Präzise Projektion und damit die Positionierung von Schnitt-, Biege- und Formlinien auf allen Metallteilen mit dem ProDirector.

Millimetergenaue Positionierung mit den Schweißdaten aus den CAD-Programmen. Vereinfachte, beschleunigte Qualitätskontrolle.

Bei der Arbeit mit Stahlbindern werden Rüstzeiten um bis zu 70% reduziert. Nahtlose und schnelle Anpassung bei Änderungen.

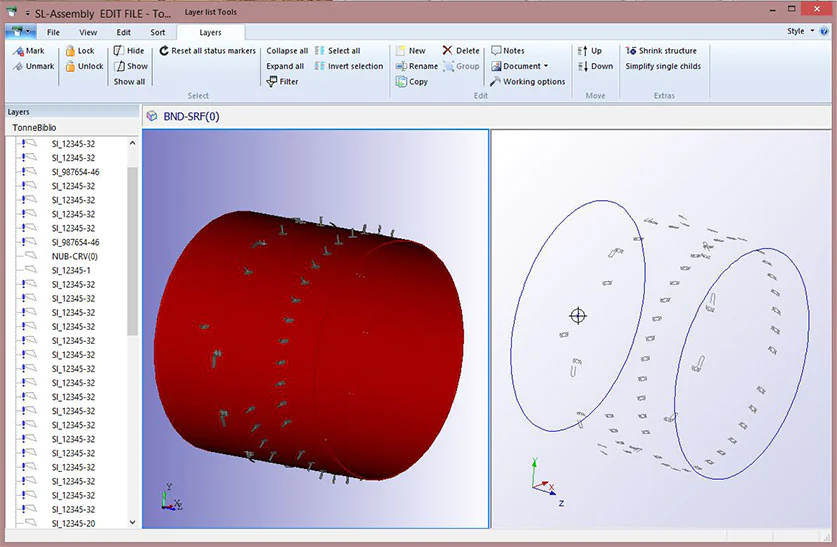

Kompatibel mit CAD-Systemen, wird die serielle Darstellung der Arbeitsschritte und die parallele Arbeit von Teams unterstützt.

Typische Einsatzbereiche unserer Laser in der Metallindustrie

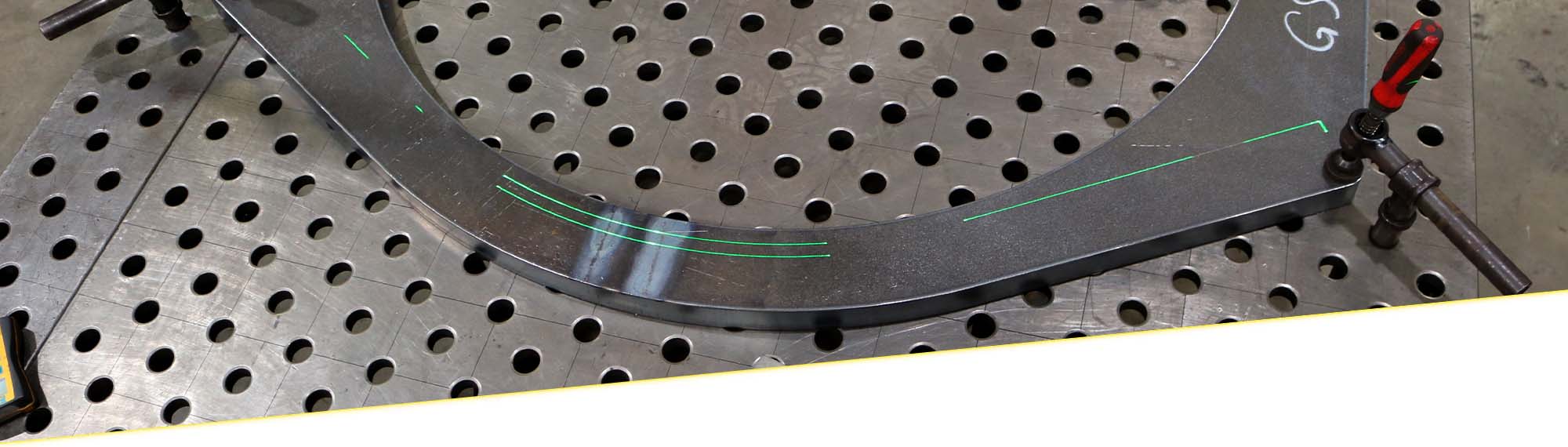

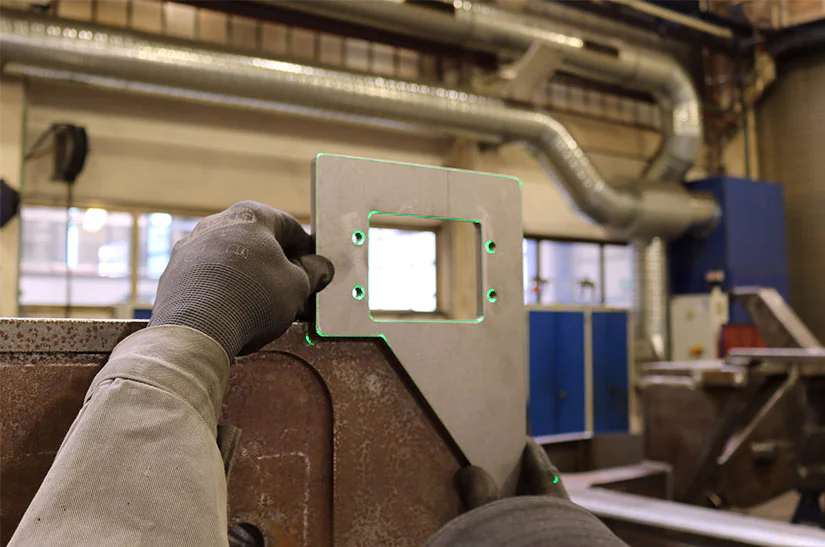

Im Layout-Prozess von Metallteilen erlauben die Laserprojektoren von SL Laser die exakte visuelle Darstellung von Entwürfen auf dem Rohmaterial. Sie markieren die Schnittlinien und Konturen für das Zuschneiden von Metallteilen und helfen bei der genauen Markierung von Biege- und Formlinien. Mit dem ProDirector 7 vereinfacht sich die korrekte Ausrichtung der Metallteile, bevor die präzise Positionierung und Führung für Schweißarbeiten auf den Schweißnähten startet. Für die Bohr- und Fräsarbeiten zeigt er die genauen Positionen und Tiefen. Schließlich wird die korrekte Positionierung der Komponenten während der Montageprozesse unterstützt.

Weitere Informationen zur Anwendung in der Metallindustrie

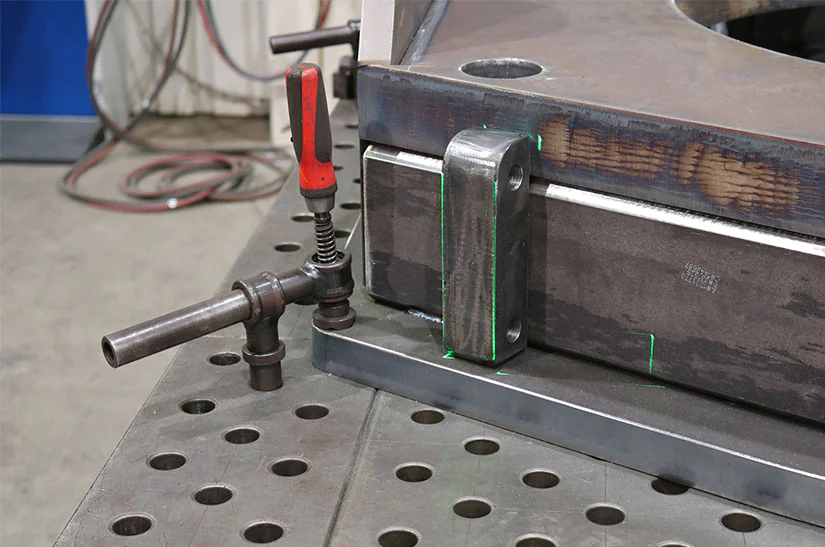

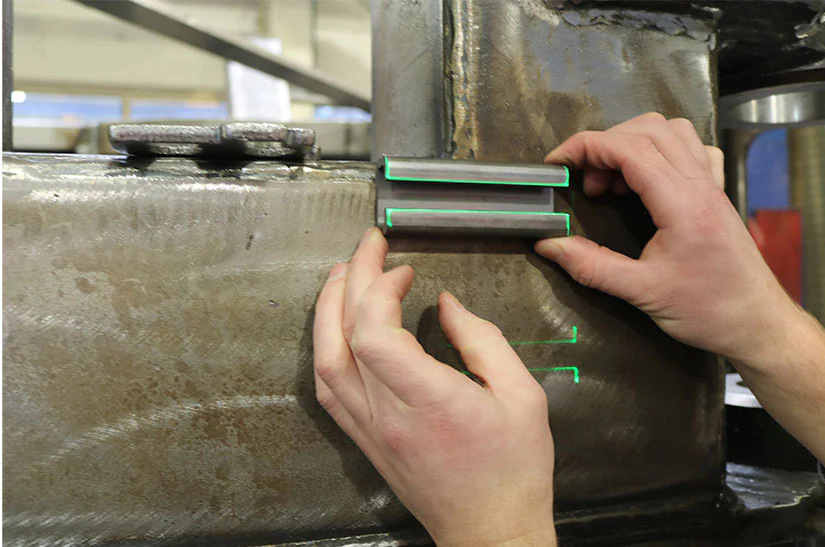

Die Laserprojektion am Schweißtisch

Mit dem ProDirector 7 wird die Arbeit am Schweißtisch maßgeblich erleichtert. Die Daten für die Projektion stammen direkt aus dem CAD-Programm und werden von jeder Höhe aus maßstabsgetreu projiziert. Der Maßstab von 1:1 erleichtert dabei nicht nur die millimetergenaue Positionierung der Werkstücke, sondern erlaubt auch die exakte Ausrichtung der Spannmittel.

Ohne aufwendige Schablonen werden alle Rüstvorgaben präzise umgesetzt und keine Anbauteile mehr vergessen. Die üblichen Rüst-Wiederholungen werden mit der Projektion zum Kinderspiel. Die Qualitätskontrolle wird stark erleichtert und gleichzeitig gespeichert.

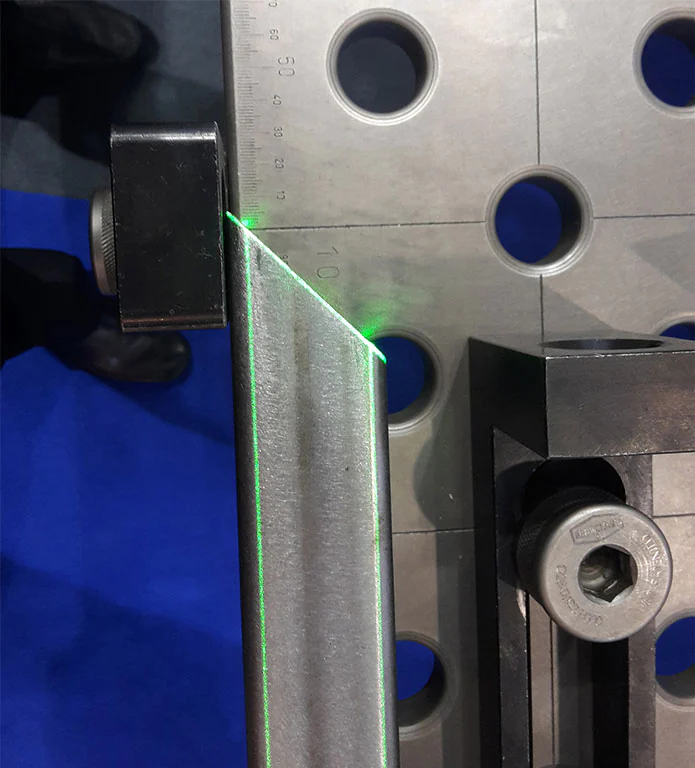

Der ProDirector 7 im Einsatz für Stahlbinder

Die Rüstzeiten für Stahlbinder stellen üblicherweise einen enormen Zeitaufwand dar. Dieser Aufwand lässt sich mit dem ProDirector 7 um bis zu 70% reduzieren. Mit der Projektion im Maßstab 1:1 wird zunächst die Kontur des Binders millimetergenau dargestellt. Im nächsten Schritt zeigt der ProDirector ferngesteuert die Anschlagposition und die exakten Positionen für die Verschraubungen. Die Einrüstung einer Applikation kann somit in kürzester Zeit erfolgen.

Falls sich der Rüstzustand ändert, schickt die eingesetzte Software die geänderten Daten an den ProDirector, der sofort die neuen Positionen anzeigt.

Softwaregesteuerte Laseranwendungen im Metallbereich

Die Software LaserPilot gehört zum Softwareprogramm, das bei SL Laser speziell für die verschiedenen Branchen entwickelt wurde. Sie ist kompatibel mit den üblichen CAD-Systemen und konvertiert die benötigten Daten mühelos. Damit erhöht sich die Produktivität der Arbeit. Zeichnungen können praktisch ohne Zeitverlust umgesetzt werden.

Sich wiederholende Tätigkeiten werden aufgezeichnet und einfach als Muster gespeichert. Mit diesen Mustern und z.B. mehreren Laserprojektoren wird auch der Einsatz parallel arbeitender Teams möglich, so dass der Durchsatz an Bindern erhöht wird. SL Laser arbeitet für Ihren Gewinn.